- Home Page

- Company Profile

-

Our Products

- Digital Clock

- Gas Transmitter

- Fan Controller

- Jumbo Display

- Level Controller

- Process Instruments

- PC-72 Process Controller

- PC-48 Process Controller

- PC48-1 Process Controller

- PC-50 Process Controller

- PC-60 Process Controller

- TCP44 Process Controller

- DOOR INTERLOCK SYSTEM

- Fixed Gases Transmitter

- Process Indicator

- LOOP POWERED INDICATORS

- POWER - MOTOR CONTROL CENTRE

- RESISTANCE TEMPRATURE DETECTOR

- TEMPRATURE CONTROLLER

- Thermowell DPM

- Timer DPM

- TOP MOUNTED LEVEL SWITCH

- Digital Timer

- Process Indicator

- Process Controller

- VOC Meter

- Panels

- PCC & MCC CONTROL PANELS.

- AUTO MAINS FAILURE PANELS

- Auto Mains Failure Control Panel

- ANNUNCIATOR PANEL

- Annunciator Control Panels

- APFC PANEL

- Automatic Power Factor Correction Control Panel

- CONTROL & RELAY PANELS

- CONTROL & RELAY CONTROL PANELS

- CONTROL DESK & MIMIC PANELS

- Control Desk and Mimic Panels

- ELECTRIC FEEDER PILLARS PANEL

- LIGHTING - POWER DISTRIBUTION PANELS

- ELECTRIC FEEDER PILLARS CONTROL PANEL

- MARSHALLINGS PANELS

- BLOW-FILL-SEAL (BFS) FILLING MACHINE CONTROL PANEL

- BLENDING & MIXING EQUIPMENT CONTROL PANEL

- PLC BASED PROCESS CONTROL PANELS

- FLUIDIZED BED DRYERS (FBD) CONTROL PANEL

- SOFT STARTER PANELS

- ROTARY CONE VACCUM DRYER (RCVD) CONTROL PANEL

- VARIABLE FREQUENCY DRIVE PANELS

- AIR TRAY DRYER (ATD) CONTROL PANEL

- VACCUM TRAY DRYER (VTD) CONTROL PANEL

- AGITATED VACCUM DRYER (AVD) CONTROL PANEL

- STEAM STERILIZERS CONTROL PANEL

- AUTOCLAVE CONTROL PANEL

- MTR Recorder

- Data Logger

- Contact Us

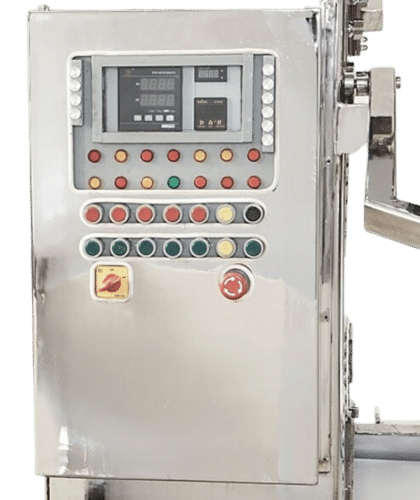

ROTARY CONE VACCUM DRYER (RCVD) CONTROL PANEL

400000 INR/Number

Product Details:

- Base Material Metal Base

- Product Type Other

- Material Metal Base

- Surface Color Other

- Rated Voltage 220 Volt (V)

- Warranty 1 Year

- Click to view more

X

ROTARY CONE VACCUM DRYER (RCVD) CONTROL PANEL Price And Quantity

- 400000 INR/Number

- 01 Number

ROTARY CONE VACCUM DRYER (RCVD) CONTROL PANEL Product Specifications

- 220 Volt (V)

- Other

- Other

- Metal Base

- 1 Year

- Metal Base

ROTARY CONE VACCUM DRYER (RCVD) CONTROL PANEL Trade Information

- 10 Number Per Month

- 10 Days

Product Description

The Rotary Cone Vacuum Dryer (RCVD) Control Panel is a specialized system designed to manage the drying process in rotary cone vacuum dryers, which are used for sensitive materials that require gentle and efficient drying under vacuum conditions. This control panel provides precise control and monitoring of the drying parameters, ensuring optimal performance and product quality. The RCVD control panel integrates seamlessly with the dryers automation system to regulate critical factors such as temperature, vacuum pressure, and rotation speed.

Featuring a user-friendly interface, the control panel allows operators to easily set and monitor parameters like drying temperature, vacuum level, and rotary speed. Real-time data display and diagnostics help in maintaining the desired drying conditions and promptly addressing any issues. The panel is equipped with advanced control features, including PID controllers for temperature and pressure regulation, variable frequency drives for rotation speed control, and alarms for fault detection.

Constructed with rugged materials, the RCVD control panel is built to endure the demands of industrial environments, including exposure to high temperatures and vacuum conditions. Safety features such as emergency stop buttons, alarms, and protective enclosures ensure safe operation and safeguard both personnel and equipment. The panels modular design allows for customization to meet specific drying process requirements, offering flexibility for various applications.

Key Functionalities of RCVD Control Panel:

- Temperature Regulation: Precise control of drying temperature using PID controllers.

- Vacuum Control: Manages vacuum pressure levels to ensure efficient drying under low pressure.

- Rotation Speed Control: Adjusts the rotation speed of the cone for uniform drying.

- Real-time Monitoring: Provides live data on temperature, vacuum pressure, and rotation speed.

- Fault Detection: Includes alarms and diagnostics for early detection of faults.

- User-friendly Interface: Features an intuitive touch screen or control panel for easy operation.

- Data Logging: Records operational data for process optimization and quality assurance.

- Automation Integration: Compatible with SCADA or PLC systems for remote monitoring and control.

- Recipe Management: Stores and recalls drying recipes for consistent product quality.

- Safety Features: Equipped with emergency stop buttons and protective enclosures.

Applications of RCVD Control Panel:

- Pharmaceutical Industry: Manages the drying of sensitive pharmaceutical ingredients and formulations.

- Chemical Industry: Controls the drying of chemical powders and compounds under vacuum.

- Food & Beverage Industry: Oversees the drying of heat-sensitive food ingredients and additives.

- Nutraceuticals: Manages the drying of dietary supplements and health-related powders.

- Cosmetics Industry: Controls the drying of delicate cosmetic powders and ingredients.

- Plastic & Polymer Industry: Manages the drying of polymer materials and plastic granules.

- Agricultural Products: Oversees the drying of fertilizers, seeds, and other agricultural materials.

- Paints & Coatings: Controls the drying of pigment powders and other components in paint production.

Enter Buying Requirement Details